Pioneering bioinspired heart valves

Next-generation 3D-printed heart valves: inspired by nature, engineered for life

3D printing heart valves to last a lifetime

The team at Corametix aim to transform heart valve treatment with their durable 3D-printed polymeric heart valves that mimic natural valve performance

Problem

Today’s valves are failing tomorrow’s patients

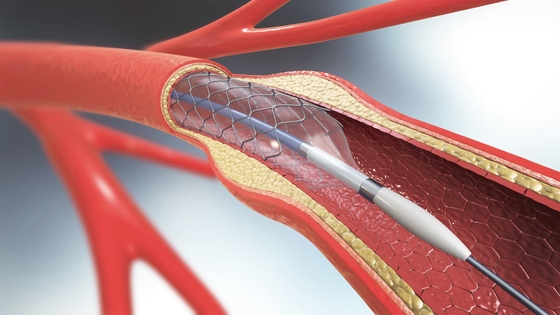

Aortic stenosis is a common, life-threatening heart valve disease, affecting 1 in 8 people in Australia over the age of 65.Without intervention, severe cases have a 50% mortality rate within two years. Aortic valve replacement is the only treatment. This procedure is increasingly being conducted via a transcatheter - transcatheter aortic valve replacement (TAVR) - as a less invasive alternative to open-heart surgery.

However, existing valves are not designed to meet long-term needs. Bioprosthetic valves compatible with TAVR often fail within five years, requiring high-risk reoperation, while mechanical valves require lifelong anticoagulation medications.

Traditional valve manufacturing processes are also expensive and extremely labour-intensive, involving up to 150 staff and 40 days per valve. This limits affordability and scalability, making life-saving treatment inaccessible for many.

As TAVR expands to younger, more active patients, the limitations of current valve technology are increasingly untenable. There is a critical need for next-generation valves that combine long-term durability, biocompatibility, and affordability – at a global scale.

Solution

Precision-engineered valves, designed for life

CoraMetix is transforming heart valve technology with durable, 3D-printed polymeric valves that closely replicate the structure and function of natural human valves, to help ensure safer and longer-lasting solutions for people with aortic stenosis.

This patented microarchitecture is engineered for long-term durability – designed to last a person's lifetime, far surpassing current bioprosthetic options and eliminating the need for repeat surgeries and lifelong medications associated with traditional options. This innovative device seeks to ensure superior strength and flexibility while maintaining safety and compatibility with minimally invasive TAVR procedures. This expanded durability can open the door to treating younger patients (aged 50–65) with moderate disease who are not currently eligible for TAVR.

Impact

Transforming valve care – for every patient

This innovation seeks to tackle key gaps in valve treatment, offering a scalable solution to help improve outcomes and ensure life-saving access worldwide. By delivering a valve that is designed to last a patient’s lifetime, it can reduce the need for repeat surgeries, lower healthcare costs, and improve long-term outcomes – especially for younger patients who currently face the burden of valve failure within years.

Using an innovative automated manufacturing process, the cost per valve is targeted at under $100, making them affordable and accessible globally, including in underserved regions. Patients everywhere can benefit from a safer, longer-lasting solution that restores natural valve function and quality of life. Beyond addressing aortic stenosis, this technology can treat other valve diseases like mitral and tricuspid regurgitation.

This isn’t just a new valve – it’s a scalable pathway to help create longer, healthier lives for millions. By addressing durability, affordability, and performance all at once, we can unlock the future of global heart care.

Millions suffer from heart valve disease but current treatments either wear out quickly or require lifelong medications. This makes them costly and inaccessible for many.

Abdul Ihdayhid

Project Lead

Tony’s story: from Kokoda to the cardiac ward

A fitness check before a Kokoda trek led Tony to a life-saving diagnosis: a hidden heart murmur.

After receiving an artificial heart valve, he’s now advocating for the next frontier — bio-inspired, 3D-printed valves that mimic the human heart.

“They could change lives — and eliminate a lifetime of meds like mine.”

Read how using Corametix’s technology could benefit Tony and others like him.

Meet the team

Disclaimer

The information provided on this page is for general informational purposes about our Catalyst Partner’s project only - see the Disclaimer. If you have any questions or would like more information about this project or Catalyst Partnership Grants, get in touch.

You might also be interested in

.jpg?width=560&height=auto&format=pjpg&auto=webp)

What is heart valve disease?

Heart valve disease means that your heart valve or valves don't open or close properly.

Heart procedures and devices

If you have a heart condition, your doctor may recommend different treatments, including procedures or devices.

Hybrid 3D-printed imaging device for precision heart care

A revolutionary intravascular imaging system that uses a world-first 3D-printed micro lens-in-lens that enables cardiologists to detect high-risk plaques accurately.

Last updated06 October 2025

.png?format=pjpg&auto=webp)